Amazon prepares for the "next wave" of its robotics revolution

A glimpse of the automated future of e-commerce (and the risk of technological unemployment awaiting humans).

What's worse? Working in an Amazon fulfilment centre or being unemployed permanently because a robot has taken all the jobs at these facilities?

We fear that the unfortunate folks who work in the Amazon supply chain will soon get an answer to this question as the e-commerce giant embarks on a new mission to automate its delivery centres.

During an earnings call yesterday, Andrew R. Jassy, CEO and President, said the megacorp is now working on the "next wave" of its robotics revolution.

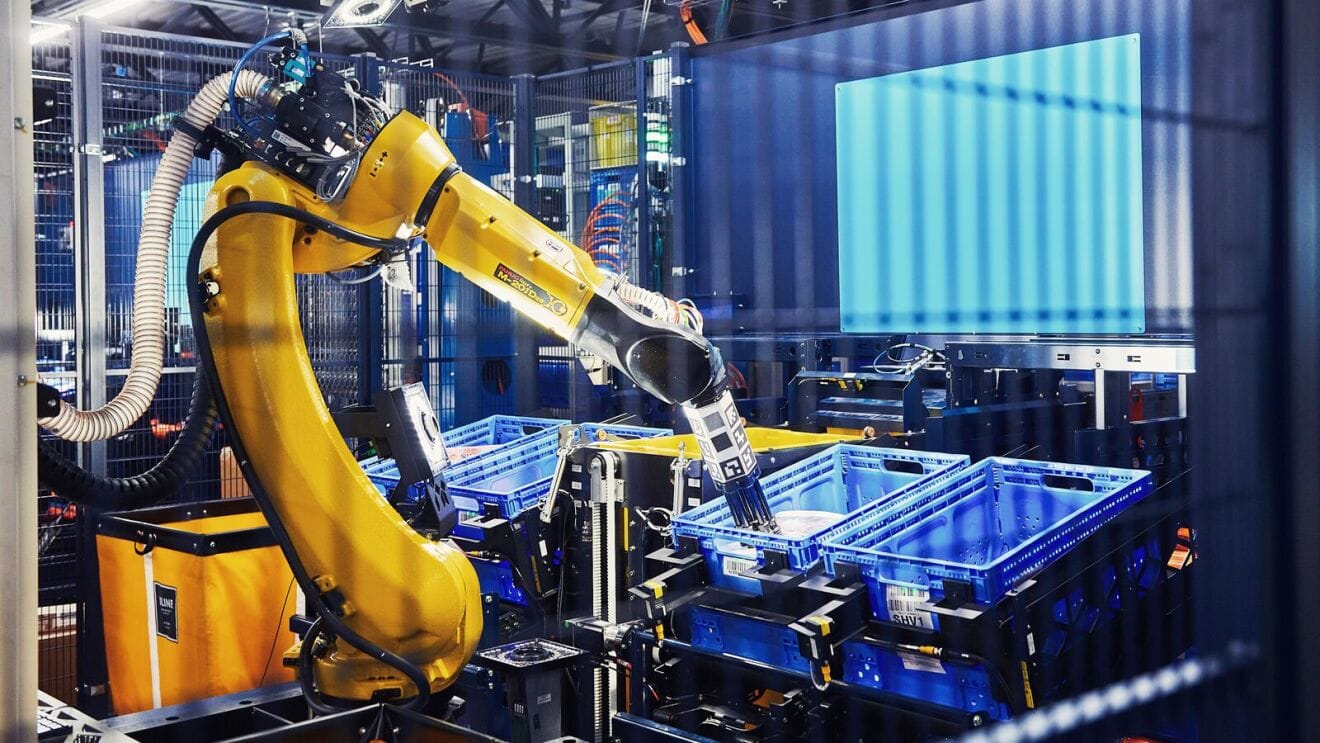

Last year, Amazon flung over the doors of its base in Shreveport, Louisiana, to show off the robots which are already working alongside humans and could one day replace them entirely, with drones or even humanoids carrying out the vital "last mile" part of delivery.

"The next tranche of robotics initiatives have started hitting production, Jassy said on the call. "And we've put them all together for the first time as part of an experience in our Shreveport facility. And we are very, very encouraged by what we're seeing there, by both the speed improvements that we're seeing, the productivity improvements, and the cost-to-serve improvements.

"It's still relatively early days, and these all being put together only in Shreveport at this point, but we have plans now to start to expand that and roll that out to a number of other facilities in the network, some of which will be our new facilities and others of which we'll retrofit existing facilities to be able to use those same robotics innovations."

Rise of the robots: The frontline of Amazon's transformation

Amazon’s exploration of robotics began more than a decade ago in 2012 when the company acquired Massachusetts-based Kiva Systems. Since then, it has developed, produced, and deployed more than 750,000 robots across its operations network.

The e-commerce titan previously claimed its goal is to equip employees with technology to make their workday "safer, easier, and more productive while delivering packages to customers faster than ever".

To which we say: OK. We're totally sure you're not planning to replace all humans with machines.

Jassy said the current raft of robotics initiatives is "not close to the end of what we think is possible".

READ MORE: Humanity faces "gradual disempowerment" rather than an AI apocalypse, researchers warn

"We have the next wave that we're starting to work on now," he added. "But I think this will be a many-year effort as we continue to tune different parts of our fulfilment network where we can use robotics. And we actually don't think there are that many things that we can't improve the experience with robotics."

Despite what cynics might say, Amazon has claimed that headcount will actually grow as it deploys the next generation of robots, which will require 30% more employees in reliability, maintenance, and engineering roles.

The takeaway? If you've got a degree and are highly skilled, you'll be able to hold down a job at Amazon.

Manual workers might want to start assessing their options.

What robots does Amazon use?

- Sequoia: This robotic system uses AI, robotics, and computer vision to consolidate inventory and free up storage space. It enables Amazon to identify and store inventory up to 75% faster by having mobile robots transport items to a containerised storage system or directly to employees picking items for customer orders. Sequoia also improves workplace ergonomics by delivering items to workstations at an optimal height, reducing the need for employees to bend or reach awkwardly.

- Hercules: A drive unit that locates and transports pods of items within Amazon’s fulfilment centres. It independently makes key navigation decisions while following overall direction from centralized planning software. Equipped with a forward-facing 3D camera, Hercules differentiates between people, objects, and other robots to ensure safe movement. It reads encoded markers on the floor to navigate accurately and locate specific pods.

- Titan: Similar to Hercules but designed for heavier loads, Titan can lift twice as much weight, allowing it to handle bulkier items such as small household appliances and pallets of food. Using computer vision, Titan picks up pods of totes and moves them efficiently through the robotics floor in Amazon’s facilities.

- Sparrow: A robotic arm that assists employees in aggregating customer orders by picking up and moving individual items from containers into specific totes. It uses computer vision and AI to identify the correct item and place it in the appropriate tote before it is packaged.

- Packaging automation: A system designed to pack customer orders efficiently while reducing environmental impact. Originally built to create plastic bags, the machine has been retrofitted to produce made-to-fit paper bags. It measures an order’s dimensions with sensors and creates a correctly sized, durable, weather-resistant package using recyclable materials. More than 120 of these machines have been installed in over 20 fulfilment centres across the US, helping Amazon avoid using more than 130 million plastic bags annually.

- Robin: Amazon’s first robotic arm, designed to sort packages before they are moved to the outbound dock for loading onto delivery trucks. Robin grabs packages from conveyor belts and places them onto robotic drive units, ensuring efficient movement. It also identifies and transfers damaged packages to maintain quality control.

- Cardinal: A robotic arm similar to Robin but equipped with advanced AI and computer vision. It selects individual packages from a pile, lifts them with air suction, reads the labels, and precisely places them in the correct cart before they are transported to the loading dock. Cardinal can handle packages weighing up to 50 pounds, reducing the risk of injury for employees.

- Proteus: Amazon’s first fully autonomous mobile robot, capable of freely navigating fulfilment centres using sensors to detect and avoid obstacles. Unlike Titan and Hercules, which operate in restricted robotic zones, Proteus moves throughout the site without the need for barcode-guided navigation. It works alongside Cardinal by transporting carts of packages from the outbound dock to the loading dock, where they are loaded onto trucks for delivery.

Have you got a story or insights to share? Get in touch and let us know.